Our Process: From Concept to Completion

A streamlined approach to precision manufacturing and engineering.

We follow a well-structured and efficient process to ensure high-quality manufacturing solutions. From the initial idea to the final product, our step-by-step approach guarantees precision, reliability, and cost-effectiveness. With a focus on quality control at every stage, we deliver results that exceed expectations.

Designing & Innovation

Design is one of several paradigms necessary for successful innovation in manufacturing. It contributes to value creation and capturing innovations in firms. We follow a human-centric approach to co-create solutions. Our deep research capability helps us develop meaningful, game-changing, and desired products that enhance user experience and market competitiveness.

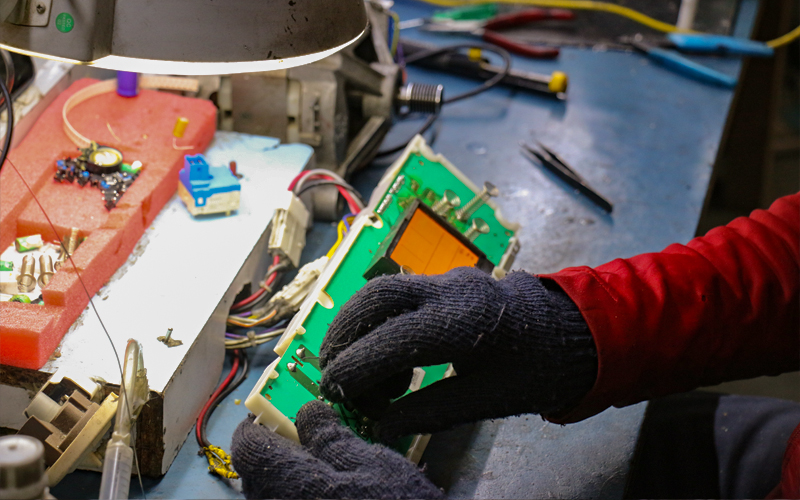

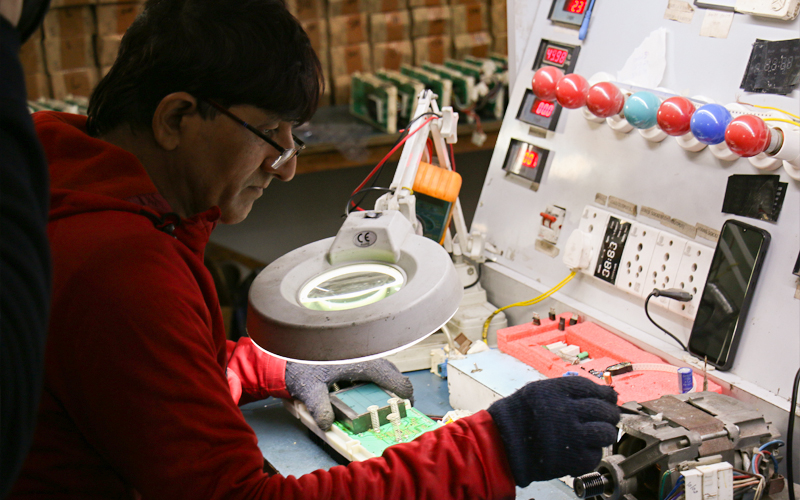

Tool Room Workshop

Our Tool Room Workshop is equipped with advanced machinery to manufacture high-precision tools and components. We specialize in designing, developing, and maintaining tools for various industries. With skilled professionals and cutting-edge technology, we ensure accuracy, efficiency, and durability in every tool, supporting seamless production processes.

Cutting & Machining Shop

Our Cutting & Machining Shop specializes in precision machining, including milling, turning, and grinding. We work with various materials, ensuring tight tolerances and superior finishes. Our state-of-the-art equipment enables efficient production of complex components, meeting industrial standards and customer requirements with high accuracy, reliability, and consistent quality.

Welding & Grinding Shop

Welding of metal tubular components to fittings and brackets is crucial for fabricating automotive parts. It is also used in manufacturing industrial items for agricultural machines, gas, and appliances. Shiva Universal specializes in welding Stainless Steel, Carbon Steel, and Aluminum, ensuring strength and durability in various industrial and automotive applications.

Phosphating Treatment

The 7-Tank Phosphating Treatment enhances metal surface durability by applying a protective phosphate coating. This process improves corrosion resistance, paint adhesion, and overall product longevity. Our systematic treatment ensures superior surface preparation, making it ideal and for industrial applications, automotive components, and machinery, ensuring high-performance.

Powder Coating Facility

Our Powder Coating Facility features an advanced automated conveyor system from Gema Switzerland GmbH. This durable finishing process provides excellent corrosion resistance and eliminates volatile organic compounds, making it eco-friendly. The method enhances surface protection, ensuring high-quality coatings for industrial products while maintaining superior adhesion.

Quality

Quality assurance ensures every product meets industry standards before delivery. Our rigorous quality control process follows a structured management system to maintain consistency, durability, and precision. We prioritize high standards in manufacturing, testing, and inspection, ensuring defect-free, reliable products that exceed customer expectations, enhance performance, and support long-term industrial applications.

Injection Moulding Facility

Our Injection Moulding Facility specializes in high-pressure polymer injection to create precision-molded components. The process includes clamping, injection, cooling, and ejection, lasting 2 seconds to 2 minutes. With advanced machinery and strict quality control, we ensure high accuracy, efficiency, and durability in producing customized industrial and commercial plastic components.